FAQ: How is it that carbon monoxide migrated from my furnace room into the rest of the house?

Short Answer: Gaps around where the furnace filter fits into the furnace cabinet will allow for a recirculation of exhaust products that are released in the furnace room.

How is it that carbon monoxide migrated from my furnace room into the rest of the house? High levels of carbon monoxide in the exhaust can escape the flue system and be recirculated into the house, through corroded pipes and be recirculated by the forced air fan.

From our video post cast on FAQ’s for carbon monoxide poisoning featuring our attorneys, Gordon Johnson and Griff Winthrop:

Gordon Johnson: So how do we get a negative pressure/suction situation from a normal forced air furnace in a house?

Griff Winthrop: It depends on the type of furnace that it is, and most furnaces these days are induced draught. We saw an example of that in that photograph. But there are still in service a lot of furnaces that are natural draught. And they are they are dangerous unless they’re really, really monitored. And that’s because they need stack effect in order to pull the air into them from the room that they’re in and get it out. So it uses hot air rises in the smokestack, it pulls the air across the burners from inside the room, and then it pushes, it sucks, if you will, through negative pressure in the stack. It sucks the carbon monoxide or the products of combustion out of the furnace and outside.

Gordon Johnson: All right. I’m going to put my fourth grade teacher hat on now, maybe seventh grade teacher, and see if I can help explain some of the the terms that Griffiths just used. All right.

So how does a furnace, where does a furnace get the air it needs for combustion? Furnaces need to breathe. We breathe so that we can combust the fuel inside our bodies–inside of our cells. Like us, furnaces have to breathe.

So traditionally, furnaces were what’s called natural draught, meaning the only way it sucked oxygen into the flame was through the suction that’s created by hot air rushing up the chimney when something’s burning inside of it. That’s called a natural draught appliance or a gravity draft appliance. All right, because these furnaces use gravity as hot air is lighter than cold air. So hot air will rush up.

You create a chimney, an exhaust pipe, and you’ve created what Griff called a stack, a stack effect, where the hot air is rushing up, and when it rushes up the stack, it creates a vacuum behind it. This is negative pressure, which pulls the cold air from the furnace room up through the combustion chamber in the furnace on its way up the chimney.

Current appliances, what I call high efficiency appliances, get all of the air from outside. There will be two pipes, that actually go outside usually through sidewalls of the house. They don’t even go up to the roof of your house. The first pipe brings cold air in. Fresh air, 21% oxygen in, and the other pipe sends out reasonably warm air, but not hot air, because high efficiency appliances take most of the heat out of exhaust before it sends it out and sends it out to sidewall.

So in between the most modern system of the high efficiency sidewall venting type appliances, where you bring in dedicated oxygen for this appliance and the natural draft concept is the inducer draft furnace. And tell us what that is, Griff.

Griff Winthrop: Well, we saw that picture. It’s a furnace that mechanically sucks the air through a fan into the front of the furnace and then mechanically pushes the products of the combustion once it once the air goes across the burner plates and is used in combustion, it pushes the exhaust up the smokestack.

Gordon Johnson: All right, so where is that induced draft furnace getting its oxygen from.

Griff Winthrop: Oxygen from the same place the natural draft appliance is getting. It’s getting it from the room that it’s sitting in.

Gordon Johnson: And the reality is, even though it does push the exhaust into the exhaust pipe, it doesn’t actually push it all the way up. It just basically is giving it a boost, just like you’re running behind the kid on the bicycle and you give it a shove. That’s all it’s really doing.

Griff Winthrop: That air is still hot when it’s being pushed, and once it hits the stack, the smoke stack, the hot air will rise like it does in the natural draft appliance. But it it does, like you said, get that initial push from the inducer, draft the inducer motor.

Gordon Johnson: Now the safest principle is probably the old one. The natural draft furnaces in many ways had fewer problems because there was fewer things that could break. The advantage of the high efficiency is that you are always, in theory, burning outside air. And even if there’s a problem with the exhaust, you may not have a high carbon monoxide levels because you’re still bringing in good air to burn.

Griff Winthrop: It’s not burning its own exhaust. Correct?

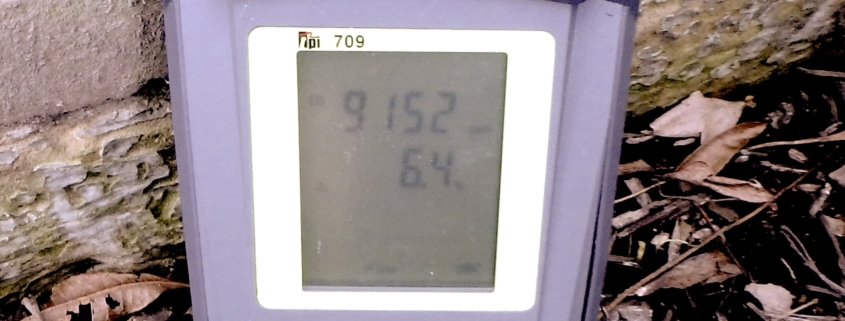

How is it that carbon monoxide migrated from my furnace room into the rest of the house? It gets circulated through the house by the forced air fan. The older the furnace, the more likely that there will be gaps where the carbon monoxide which leaks out of the combustion chamber or exhaust gets recirculated. Here, this 40 year old furnace had such dirty burners that the exhaust contained 9,000 ppm CO in the exhaust. Once that escape the corroded pipes, the forced air fan sent it everywhere in the house.

Gordon Johnson: The inducers almost always have problems when something breaks on them, because they are dependent on that motor to bring in fresh air. And if the safety switches aren’t such that it will shut off the combustion and it continues to run, you’re virtually guaranteed to get significant levels.

All Natural Draft Furnaces are Too Old to be Safe

The problem with natural draft furnaces is that they are all obsolete. Since they haven’t been made since the 1980’s, they are decades past their useful like and even though they have fewer moving parts to break, they aren’t meant to last more than 25 years.

There is a significant percentage of large apartment complexes built before we had high efficiency furnaces. In our experience, out of 400 furnaces in such complexes, only a handful will have been replaced. Structural components of those natural draft furnaces will break, such as the heat exchanger, and when that happens, high carbon monoxide levels will poison apartment occupants.

The furnace on the left was a furnace in a beautiful historic home, where the owner claimed not to believe that this 40 plus year old furnace was even being used. An experienced HVAC tech who was assisting our engineer took one look at the burners of this furnace and said there was going to be high levels of CO, even if the heat exchanger was intact. He was right. The CO levels in the exhaust were measured at 9,152 ppm. See above picture of the combustion analysis on this old furnace.