Low Carbon Monoxide Generators are being made now

In testimony before the U.S. ‘Consumer Products Safety Commission, the head of one of the United States leading portable generator manufacturers said that low carbon monoxide generators are not only necessary, but feasible. On March 8, 2017, Lee Sowell with TTi testified to the CPSC that the agencies initiative was important, necessary and could be done affordably. He also testified that TTi was currently manufacturing generators that complied with the CPSC proposed standard.

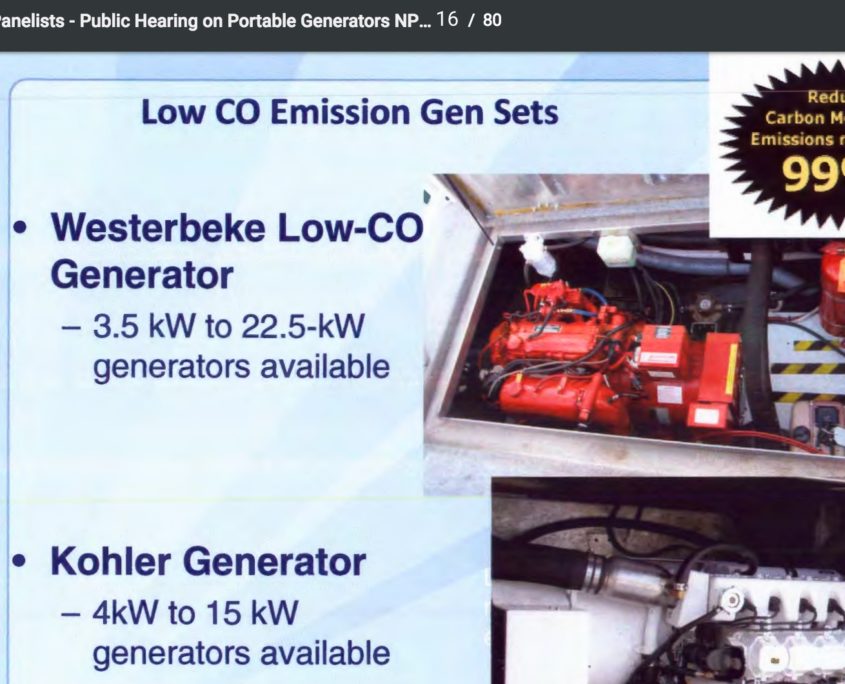

Low carbon monoxide generators are feasible according to the head of a major generator manufacturer, TTi. One wonders why if the marine generators got there in 2004/2005, the rest of the portable generators industry is still making excuses.

Among the highlights of Sowell’s testimony were his whole hearted support of the CPSC Proposed Rule and announcing that TTi was prepared to launch multiple low carbon monoxide generators in 2017. One wonders why if TTi can be making these generators now, why the rest of the industry is fighting the clear safety advantages of low carbon monoxide generators. Said Sowell: “I would like to point out that at the PGMA Technical summit in March 2016, we were the only company that publicly presented the results of our reduced CO emission development efforts.” The rest of PGMA has been denying the value of the CPSC’s proposed rule and making excuses why low carbon monoxide generators can’t be done after 15 years of the CPSC pushing this issue.

Mr. Sowell’s prepared remarks on low carbon monoxide generators are posted below in full.

Oral Testimony of Mr. Lee Sowell:

President, Outdoor Products Division, Techtronic Industries Power Equipment.

Before the U.S. Consumer Product Safety Commission Portable Generator NPR March 08, 2017

Good morning. My name is Lee Sowell and I’m the President of the Outdoor Products Division for Techtronic Industries Power Equipment, known as TTi. As a major manufacturer of outdoor power equipment including portable generators, TTi sells product under the Ryobi, Blackmax and Powerstroke brands to major retailers like The Home Depot and others. Though industry data is limited for determining US generator market share, I estimate that we are the 41 h largest supplier of portable generators in the industry. We have a manufacturing facility in Anderson, South Carolina where we produce a portion of our generators. We also have overseas manufacturing capabilities.

I want to thank the Commission and CPSC staff for their leadership in this important topic. We share the CPSC’s goal of ensuring the safety of all consumer products sold to U.S. consumers. I’d also like to point out that we are one of the founding members of the PGMA and we are active on the Board of Directors and also Chair the PGMA Technical Committee.

TTi is here today to publicly support the Portable Generator NPR because it promotes a technical standard that will address the CO hazard associated with portable generator in enclosed, partially enclosed mis-use scenarios and as well as outdoor use scenarios. We offer our comments from the perspective of a finished goods manufacturer of portable generators, who has a track record of consistently demonstrating that product safety is of the utmost importance to our company. Today, I will highlight our support with the proposed rule; and how TTi has spent significant time and resources doing the R&D and testing of low CO emissions to prove the technical feasibility of the technology.

TTi wholeheartedly supports the CPSC’s mission of product safety and the proposed rule to limit the CO emissions rate of portable generators at the source. This is, in our opinion, the most sure way to directly reduce the chances of injuries and fatalities as a result of the mis-use of portable generators. To illustrate my point let me refer you to an example case that was included in a recently submitted comment to the Portable Generator NPR site. Ed & Cristine Watson, from Clarksville TN , lost a daughter, a husband and three friends due to carbon monoxide poisoning after operating their generator outside of their camper. Like most consumers, the Watsons, despite warning labels provided, may not have realized how dangerous generator exhaust can be resulting in mis-use. From the Watson’s perspective they were operating the generator correctly -it was not inside the camper. Rather, it was intentionally placed outside. Unfortunately, placing the generator outside was not enough to avoid a tragic accident. This scenario and many others like it will most likely not be prevented by shut off technology alone. Rather, the most effective way to mitigate the potential for CO related injury is to first address the hazard at its source -by lowering the amount of CO produced -and then focusing on shut off technology.

The work that the CPSC did in conjunction with the University of Alabama to make a working prototype demonstration provided us a solid foundation of technical understanding and a very helpful framework of reference points that helped guide our development teams to achieve CO emission results that were otherwise thought to be unachievable for portable generators. My teams have been able to demonstrate low CO emissions on many different engines and engine sizes, as well as successful demonstrations using multiple fuel types. With each passing phase of development, my teams are making further discoveries, improvements and helping to push the base on knowledge and understanding of what the technology is capable of achieving, and how it fits perfectly as a technical solution to solve the CO hazard associated with portable generators.

I would like to point out that at the PGMA Technical summit in March 2016, we were the only company that publicly presented the results of our reduced CO emission development efforts. Since then, we have continued our development and have been able to incorporate a shut-off technology that does not rely on chemical sensing devices and has the potential to demonstrate higher reliability. The optimal solution for limiting the CO hazard would be prevention via reduced CO emissions and detection via a shut-off feature. We have been working with multiple partners that combined have significant technical experience to enable us to replicate the University of Alabama results and make it commercially viable reduced CO emissions technical solution. The technology to reliably control CO emissions on small engines is readily available on the market today from multiple sources. Anyone who is serious about addressing this hazard can do so today.

We have plans to launch multiple generators during the 2017 calendar year using our own reduced CO emissions engines, and also using other third party engines that are readily available on the market. Kohler announced in October 2016 that they have developed an engine for use on portable generators which has a reduced CO emissions rate and we are proud to partner with them to resolve this CO hazard and improve the health and safety of US consumers. We ~e also partnering with another engine manufacturer from Japan and we welcome the opportunity to work with others. TTi remains strongly committed to working with industry to address the hazards associated with the use of portable generators. We do appreciate the opportunity to provide our view on the proposed rule. Thank you. I am happy to answer any questions you may have.

Leave a Reply

Want to join the discussion?Feel free to contribute!